It had the second largest production of any of the larger Rivett lathes, about 1800 total. The basic lathe changed little from its introduction in 1920 until production ceased in 1960. Approximately 1800 units were produced.

These lathes could be found in laboratory shops in places like Harvard, Johns Hopkins and Yerkes Observatory. They were present in leading edge industrial laboratory shops as well. One on display at the Charles River Museum, is listed as the first lathe at Polaroid corporation. There are several in the Edison shops in West Orange, NJ.

Part of the reason for the large production of the 608 was its popularity with the military during World War 2 where it was used on shipboard, in maintenance depots and shipped in large quantities to Great Britain.

The 608 is considered my many familiar with them to be one of the finest small lathes ever made.

608 Sales Brochure (PDF)

608 Price List from 1943 (PDF)

608 Manual (PDF)

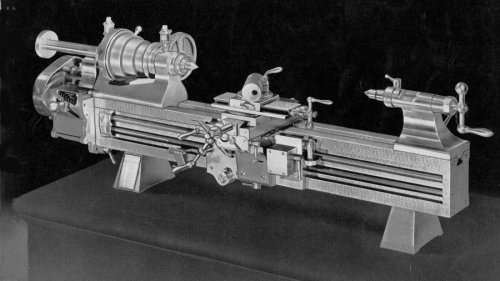

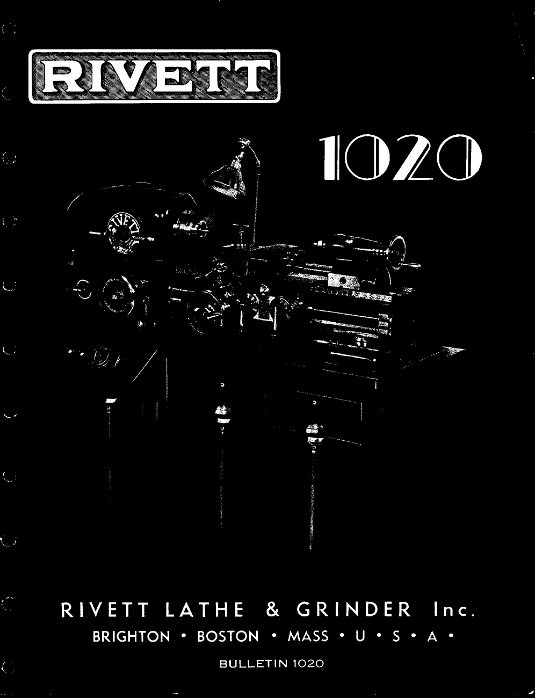

1020

Photos of actual lathes can be found in the Album section.

1020 Sales Brochure (PDF)

1020 Instruction Manual (PDF)

1020S/1030S

| The Rivett

1020S series lathes were the largest and heaviest

ever built by Rivett. The 1020S and 1030S were

built from 1949 until 1961, and differed only in

bed length. Approximately 300 units were

produced. The 1020S had a maximum distance between

centers of 20", while the 1030S increased this

distance to 30". The swing over the bed was 12 ½

inches for both machines. Machine weight was 3,800

and 4,200 pounds respectively. In the last few

years of Rivett's existence, as a subsidiary of

Leland-Gifford Co., variants of the 1020S and

1030S were produced, called the 1020F and 1030F.

These machines had an increased swing of 13 ½

inches and an electrical, rather than the earlier

mechanical, tachometer. These machines were clearly intended to compete in the same portion of the "toolroom lathe" market as the more common Monarch 10EE. The all-mechanical drive used in the Rivett machines exhibits some advantage over the Ward-Leonard (or electronic equivalent) dc-drive 10EE or even modern variable-speed drives. It incorporates a variable speed drive similar in principal, though much more heavily constructed, to that in the Hardinge HLV-H. It employs a Reeve's style variable diameter pulley system, with speed change accomplished via a small gearmotor. This arrangment potentially preserves a greater portion of the full motor horsepower at low spindle speeds than the electronic drive systems. Additional specifications, plus lubrication and owner's notes may be found here. 1020S/1030S Manual (PDF) |