| Maximum distance between centers | 20" or 30" |

| Swing over bed, diameter | 12 ½ " (13 ½" for the 1020/30F) |

| Swing over carriage, diameter | 6 ¼" (7 ¼" for the 1020/30F) |

| Spindle nose, standard | L0 |

| Spindle nose, optional | D1-3 |

| Tail stock travel | 3 ½" |

| Number of feed changes | 72, 0.001" to 0.060" /rev |

| Number of thread changes | 84, 2 to 240 threads/inch |

| Bed width | 12 ¾" |

| Carriage travel | 20" or 30" |

| Spindle speeds | 22 to 3600 RPM |

| Motor | 1750 RPM, 5HP |

| Weight | 3800 or 4200 lb (3900 or 4300 lb for the 1020/1030F) |

I've (Greg) gotten numerous requests for lubrication advice from 1020 owners. The weights recommended in one portion of the manual are SAE-40 for the headstock and gearbox, Sunoco way oil for the carriage and SAE-10 for the tailstock. In another section, entitled "Military Lubricant Specifications", the following oils are specified: Headstock, Viscosity SUV SEC. @100F, 818; Carriage: Viscosity SUV SEC. @100F, 305.

Based on this, I did a fair amount of research into the wonders of different viscosity indices and also consulted an application engineer at Mobil. The resulting recommendations are listed in the following table:

| Quantity, Qts | SAE | Saybolt Sec @ 100F | ISO | Recommendation | |

| Headstock | 10 | 40 | 840 | 150 | Mobil DTE Extra Heavy |

| Gearbox | 8 | 40 | 840 | 150 | Mobil DTE Extra Heavy |

| Carriage | 1 | 20 | 356 | 68 | Mobil Vactra #2 |

| Tailstock | 10 | 158 | 32 | Mobil DTE Light |

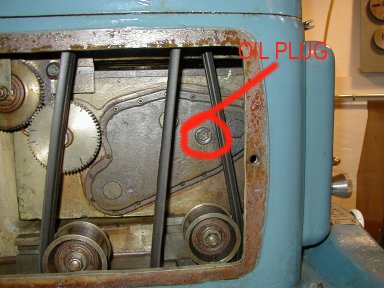

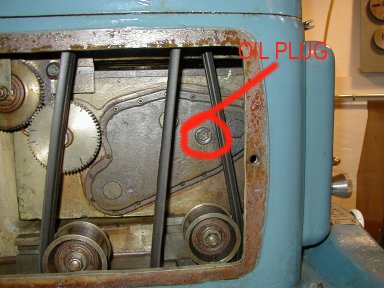

Lubricating the headstock is straightforward. Drain using the upper drain fitting on the back of the headstock, and add oil through the top plate on the headstock. The carriage is also straightforward. Drain using the pipe plug on the bottom of the carriage, and add oil to the oil cup on the front. The gearbox is a little more challenging. It is easily drained via the lower drain fitting on the back of the headstock/gearbox. The fill plug is located inside the cover over the headstock belts and pullies.

|

| 1020S/1030S Gearbox fill location |

I made a contraption out of pipe fittings that screws into the fill plug hole and extends out of the cover to a right angle fitting in which I placed a funnel. After completing my construction, I remembered a contraption made of pipe fittings that came with the lathe in the box of dull drill bits, broken taps, melted lathe bits and other junk that inevitably accompanies a used lathe. So that's what that thing was for!

Some sharp-eyed soul noticed that one of the belt tensioners is on the wrong side of the V-belt. I had moved it to get the belt out of the way while doing some work, and forgot to put it back when taking the picture. It was put in its correct place before putting the lathe in service, but my mistake is immortalized in this picture. (Belt tensioners like this always belong on the flat, non-V side of the belt.)

03/09/2006