|

The

No. 3 Bench Lathe was Rivett's first production model of a

7" bench lathe.

|

|

|

The

No. 3 Manufacturers' Lathe was what came to be known as a

"speed lathe" for production of small parts. The

half open tailstock allowed the rapid change of tailstock

tools, and "can be handled much more rapidly than a

turret."

|

|

|

The

No. 3 ˝ Bench Lathe was a 7" swing machine like the No. 3,

but built in the style of the No. 4, being finished all

over.

|

|

|

The

No. 4 Bench Lathe was a popular model, with 8" swing. It

used a similar headstock and tailstock construction to the

8" Precision, and was finished all over, scrape finished

and polished. An almost bewildering array of

accessories could be obtained to allow a wide variety of

toolroom turning, milling and grinding as well as

production turning.

|

|

|

No.

4 Bench Lathe on "bicycle" foot-power stand |

|

|

|

|

|

No.

5 Manufacturers' Lathe |

|

|

|

|

|

The

No. 505 Plain Precision Bench Lathe was for many years the

flagship plain lathe offered "for precision toolmaking and

accurate light manufacturing." Over the years, it

was provided with headstocks utilizing either double

tapered plain bearings or ball bearings and accepting 3NS,

4NS, 5NS, 5C and, remarkably, 6H collets. The usual

bewildering array of attachments was available including

turrets, ball turning rests, slotters, relieving

attachments, grinding spindles, milling attachments and a

variety of tailstocks. The 505 had the longest

production of any Rivett lathe except the 608, starting

sometime prior to 1920 and continuing until 1953.

Sales Brochure (PDF)

|

|

|

|

|

|

|

The

Rivett 507 was a less highly finished bench lathe intended

to sell for a more modest price than, for example, the

505. In earlier years of production, it was known as

the Rivett Junior Bench Lathe No. 507, while in later

years it was merely the Series 507. An emphasis on cost

was achieved "by making the design as simple as the

function of the part will permit, by avoiding machined

finish on non-working surfaces, by reducing hand labor to

a minimum, and by the employment of a new and complete

equipment of special manufacturing tools and fixtures,

which assure uniformity and aid in lowering expense."

Like the more expensive machines, a

wide variety of accesories was available for miling,

grinding, indexing and production via turret tailstocks

and lever cross slides.

Production was about 250 lathes from

1926 to 1940.

Sales

brochure from 1932 (PDF)

|

|

|

|

|

|

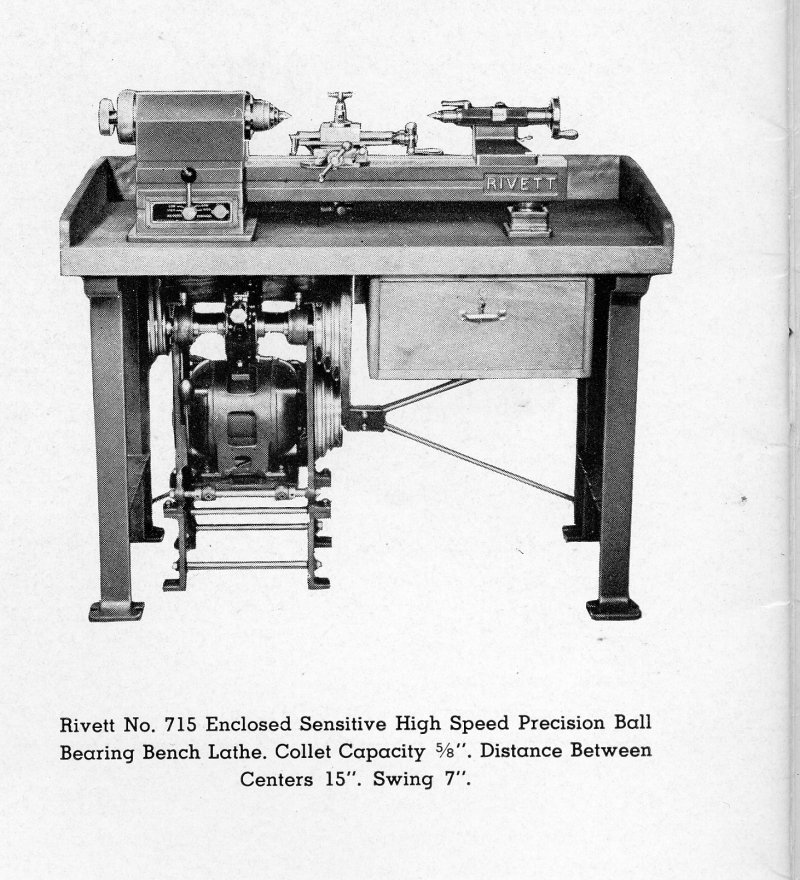

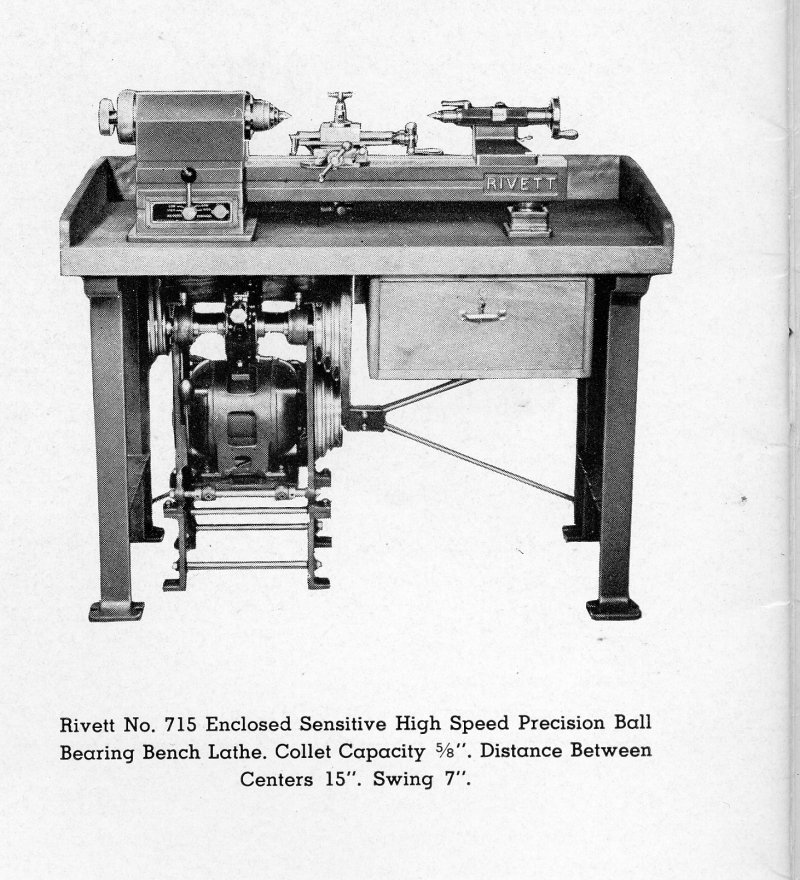

The model 715 second operation lathe was similar to

the 918 except for a reduced capacity of 7" swing and

15" between centers. It incorporated a key-drive

long taper spindle similar to, but smaller than, the

standard L00. The inside of the spindle incorporated a

4C collet seat. A two speed motor, two step pulley

between the motor and clutch box, and a dog clutch

selection between two different pulley reductions

provided eight spindle speeds between 150 and 3500 rpm.

The tailstock travel, as well as slide rest motions,

were all graduated in thousandths. The machine

weighed 650 pounds.

As was common for bench lathes of this era, a

dizzying array of accessories was available to allow the

lathe to do dividing, milling, grinding and sawing.

Production was about 180 from 1942 to 1953.

Model 715 User's Manual

(pdf)

|

|

|

|

|

|

The

model 918 second operation lathe was introduced in 1938

and ceased production in 1960. During that time, about

2100 918's were made, making it the largest production

large Rivett lathe. Like the 608, many of these were

produced during World War 2 for use in manufacturing war

materičl. |

|

|

|

|